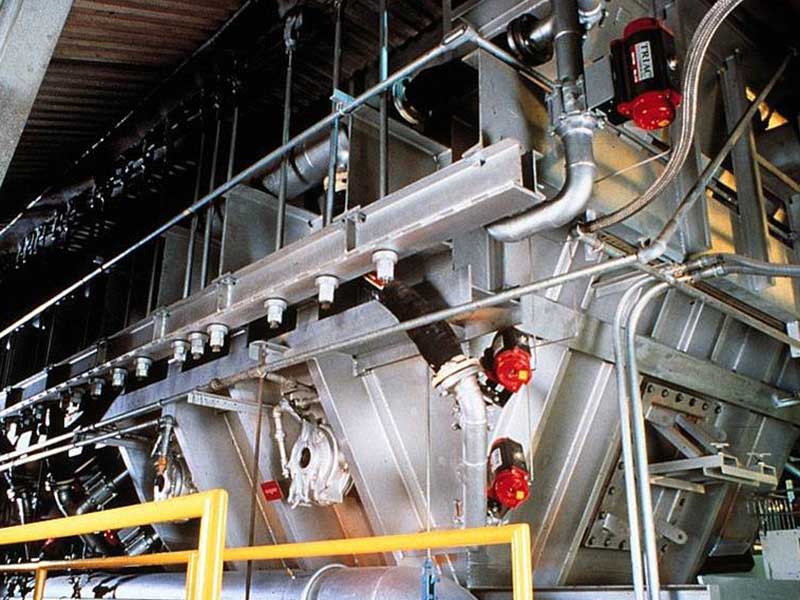

PAX Conveyor Pneumatic Ash Extractor

UCC pioneered the first dry bottom ash system using pneumatic technology in 1920. The PAX Pneumatic Ash Extractor added new technology to this time-proven vacuum system design and offers many benefits over wet bottom ash systems. The PAX system eliminates the need for water and reduces overall maintenance costs. For plant retrofits, the PAX conveyor system provides excellent routing flexibility around structural barriers.

Bottom ash is collected in refractory-lined hoppers under the boiler in the pax conveyor system. Percolating cools the ash and protects ancillary equipment from the 1600°F ( 871°C) temperature. At the appropriate time, grid doors at the hopper bottom open to allow ash and clinkers to pass into a crusher and are fed to the vacuum system for transport to the dry storage silo or ash transfer truck.

Performance Specs of Pneumatic Systems & PAX Products

• Zero water discharge – No contaminated water to treat and no ash ponds to maintain

• More complete combustion of unburned carbon

• No space required for pumps, tanks or re-circulation system

• Time-proven dependability of a vacuum conveying system

• Substantially reduced maintenance costs with no major recurring expenses

• Cleaner working area – No puddles

• Dry bottom ash can be sold and reused in environmentally friendly applications

How can we help?

Our team of experts are happy to help answer any questions you have about UCC’s solids solutions.