UCC Test Lab

The UCC commitment to quality is backed by thousands of development, testing, and evaluation hours. UCC Environmental has one of the world’s most advanced research laboratories and conveyor test loops to simulate ash and reagent handling applications and validate design parameters. Our knowledge and experience in material behavior, product innovation and system development for challenging applications is unmatched in the industry.

UCC works closely with our global customers to test and verify conveying performance before deployment at the plant to effectively manage risk.

UCC Lab Capabilities

Technology

Our test lab provides UCC’s NPD team with the capability to engineer prototypes and continually test new products and equipment to enhance existing designs. This ability enables our engineers to develop state-of-the-art technology, providing our customers with superior products and custom solutions they’ve come to expect from us.

Material Testing

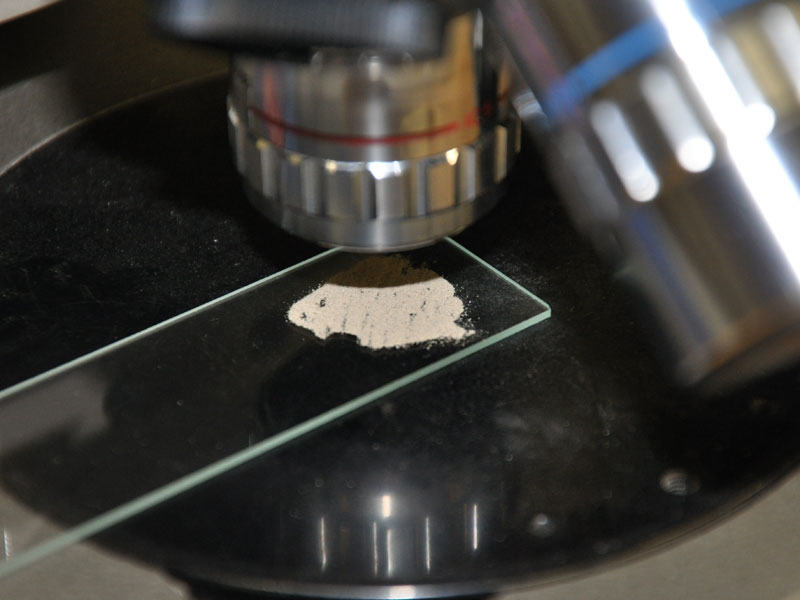

Hundreds of ash and reagent samples have been tested and analyzed in our 10,000 sq. ft. lab to ensure material performance and reliability. This testing environment allows for complete analysis of physical, chemical and conveying characteristics of material.

Testing Includes:

- Bulk Density

- Particle Density/Specific Gravity

- Fluidizability

- Sieve Size Distribution

- Laser Diffraction Analysis for particle size distribution of powders

- Microscopic Examination with Digital Photography

- Setup/Conditioning

- Pick Up Velocity

- Arching/Rat holing Index

- Permeability/Deaeratability

- Moisture Content

- LOI or Unburnt Carbon

- Thermo Gravimetric Analysis (TGA) for analyzing chemical compounds

- Scanning Electron Microscope (SEM) Analysis/Photography

- Energy Dispersive Spectroscopy (EDS)/X-Ray fluorescence (XRF) for analyzing elements

- Rheology of low/high density slurry

- Free-lime test

- Water tests – Langelier’s index, Ryzner stability index, Aggressiveness Index

- Prototype Design and Development

- Product Performance Testing and Evaluation

- Material Performance Testing and Analysis

- Failure Analysis

- Metallurgical Analysis

- Pressure, Flow, and Cycle Testing

- Physical Conveying Analysis and Evaluation

- Chemical Analysis

- Bulk Material Property Testing and Flow Analysis

- Wastewater Treatability Testing

Test Loops

Our facility contains six complete test loops which are used to simulate the behaviors of material in conveying lines under various conditions. Control systems are used to examine and control the conveying environment, and comprehensive data is collected and provided to verify determining design parameters.

Dilute Phase (Pressure or Vacuum):

- Material type: Granular

- Capacity: 1 ustph

- Pipe size: 2 inch

- Length: 100 ft

- Elbows: 7

- Down comer: 7 ft

- Riser: 8 ft + 18 ft

- Variable speed blower

- Variable speed screw feeder

- Three sight glass sections

- Load cells and pressure/vacuum transducers

- Computerized data acquisition and control

Dense Phase (DEPAC™ Bypass system):

- Material type: Granular

- Capacity: 5 ustph

- Pipe size: 4 inch

- Length: 270 ft

- Elbows: 7

- Down comer: None

- Riser: 8.5 ft + 7 ft

- Air flow control valves

- Four sight glass sections

- Load cells and pressure transducers

- Pressure/air flow/ash feed measurement

- Computerized data acquisition

Dense Phase (MultiDAC™):

- Material type: Powder

- Capacity: 25 ustph

- Pipe size: 6 inch

- Length: 870 ft

- Elbows: 18

- Down comer: 17 ft

- Riser: 8 ft + 8 ft = 14.5 ft

- Air flow control valves

- Six sight glass sections

- Load cells and pressure transducers

- Computerized data acquisition and control

Dense Phase (DEPAC™ system):

- Material type: Powder and fine granular

- Capacity: 10 ustph

- Pipe size: 3 inch and 4 inch

- Length: 500 ft

- Elbows: 14

- Down comer: 15.5 ft

- Riser: 8.5 ft + 7.5 ft +15 ft

- Air flow control valves

- Five sight glass sections

- Load cells and pressure transducers

- Computerized data acquisition and control

DSI (Hydrated lime/Trona/SBC/PAC):

- Material type: Powder and granular

- Capacity: 5 ustph

- Pipe Size: 3 inch

- Length: 100 ft

- Elbows: 3

- Riser: 13 ft

- Air flow control valve

- Three sight glass sections

- Load cells and pressure transducers

- Computerized data acquisition and control

High Density Slurry Test Loop:

- Material type: Powder and granular

- Capacity: 7 ustph slurry

- Slurry conc. up to 70% solids by wt.

- Pipe Size: 1.25 inch

- Length: 125 ft

- Elbows: 8

- Riser: 6 ft

- Batch type; batch size one 55-gallon drum

- Variable speed positive displacement pump

- Pressure transducers, slurry S.G. and slurry level measurement

- Computerized data acquisition

Other test set ups:

- 1/8th scale model CDR to test particulate settling in water.

- 1/10th scale clear flue gas duct for testing and developing sorbent injection lances.

How can we help?

Our team of experts are happy to help answer any questions you have about UCC’s service solutions.