Dry Sorbent Injection for SO2, SO3, Hg and HC

Since 2009, UCC Environmental (UCC) has pioneered dry sorbent injection technology which injects selected sorbents into the flue gas to control SO2, SO3, mercury, HF and HCI. UCC leads the industry in Dry Sorbent Injection and is recognized as the technology leader that delivers robust systems that perform. Our customers have confidence in our systems. Our experience removes the guesswork and we work closely with customers to deliver a reliable solution to each plant’s needs. We have also retrofitted 65 competitor systems that were underperforming. These systems are more efficient, using less sorbent, and are working well.

• Performance-based turnkey solutions

• Over 30,000 hours of dry sorbent injection demonstration testing

• UCC VIPER® Mill Technology delivers the highest removal efficiency and greatest cost savings

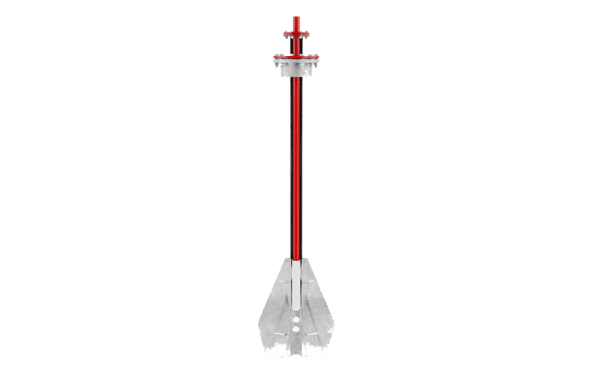

• UCC’s Patented COBRA™ Lance maximizes particle dispersion in DSI and ACI systems

UCC ENVIRONMENTAL DRY SORBENT INJECTION INNOVATION

Operational Excellence

Splitters

COBRA® Lance

CFD Modeling

DSI FOR LIME KILNS

COBRA™ II Lance

The COBRA™ II Lance has been engineered to maximize particle dispersion at the sorbent injection point in Dry Sorbent Injection (DSI) and Activated Carbon Injection (ACI) systems. The patented COBRA II Lance offers optimal efficiency over standard lances and can reduce sorbent use by 10 to 30%! The COBRA II Lance further improves emission removal performance and significantly reduces sorbent consumption.

Ecopod™

The ecopod™ is a compact, modular unit designed to provide cost-effective Hydrated Lime, Trona and Sodium Bicarbonate injection. Its stand-alone design is equipped with a simple legged silo or external hopper for sorbent storage. The ecopod incorporates both the sorbent metering and conveying equipment. Controls and power distribution equipment is also integral to the unit. A six door configuration allows for easy and safe access to its equipment and instrumentation. Its small footprint allows for installation on existing slabs or platforms.

MULTI-POLLUTANT CONTROL CAPABILITY

Many plants are looking for a single, comprehensive solution for the removal of pollutants required by EPA MATS and CSAPR/CAIR regulations. Determining factors include complex chemistry, fluid dynamics, sorbent selection, injection location and interaction with existing APC equipment such as ACI systems, fuel additives and fabric filter / ESP collection. UCC has extensive experience with simultaneous SO2, SO3, HCI, HF and Hg removal to deliver comprehensive compliance strategies in a timely and economical manner.

PROVEN MILLING TECHNOLOGY

The VIPER Mill is a proven, reliable technology developed specifically for dry sorbent injection. The UCC patented VIPER Mill operates in line with the DSI system and delivers the smallest particle size, highest throughput and greatest cost savings in the industry. The result is 30 – 50% lower sorbent usage compared with as-delivered material.

• Designed for trona and sodium bicarbonate

• Capacity: 0.5 – 7 tons per hour

• Median particle size: 9 – 15 µm (trona), 15 – 19 µm (SBC)

• Reduced sorbent usage saves millions of dollars

SKID MOUNTED INSTALLATION WITH AUTOMATED CLEANING

The VIPER Mill is equipped with an automated cleaning system to eliminate sorbent build-up. The cleaning cycle ensures consistency in particle size while balancing horsepower, temperature rise and sorbent technology throughout. The VIPER Mill uses either a simple bypass system or redundant skid for uninterrupted DSI operation.

DSI Retrofit Solutions: Upgrading Your Air Pollution Control Systems

Poor performing systems, regulatory compliance, and operational costs are all primary considerations when evaluating current Dry Sorbent Injection (DSI) technologies and equipment to optimize system performance. As many DSI system suppliers have exited the market, customers are left with unsupported systems and need alternative solutions. The absence of original equipment manufacturers has driven numerous customers to UCC to rectify their failing systems and to support their ongoing DSI needs.

Candidates for DSI Retrofit

Inconsistent Sorbent Performance: If your existing system struggles to achieve consistent particle sizing or efficient sorbent injection, a retrofit can optimize your equipment for enhanced pollutant removal.

Excessive Emissions: High levels of pollutants such as sulfur dioxide (SO₂), hydrogen chloride (HCl), or mercury indicate that your system may need an upgrade to meet current emission standards.

Frequent Maintenance Requirements: Aging or poorly performing components that require frequent repairs are signs that a retrofit could enhance system reliability and reduce downtime.

Regulatory Non-Compliance: As environmental regulations tighten, older systems may no longer meet emission limits. Retrofitting your equipment ensures compliance with the latest air quality standards.

High Operating Costs: Inefficient or outdated systems often result in higher operational costs. Retrofitting with DSI technology can reduce energy usage and improve overall efficiency.

Benefits of a UCC DSI Retrofit System

Enhanced Performance: Achieve optimal pollutant removal efficiency, helping to meet and exceed regulatory requirements while minimizing emissions.

Reduced Operational Costs: By upgrading your existing system with advanced DSI technology, you can lower sorbent usage, reduce energy consumption, and minimize maintenance expenses, leading to significant long-term savings.

Minimal Downtime: Our experienced team of DSI experts ensures that retrofitting is quick and efficient, minimizing disruption to your operations.

Long-Term Compliance: Stay ahead of regulatory changes with a retrofit that ensures your system is capable of meeting evolving air quality standards.

Improved Reliability: Reduce maintenance costs and unplanned downtime with upgraded components that improve the reliability and lifespan of your equipment.

Frequently Asked Questions

What is Dry Sorbent Injection (DSI)?

How does DSI work?

What pollutants can DSI control?

What are the advantages of using UCC’s DSI systems?

• Most reliable systems on the market

• Proven operation with over 30,000 hours of testing

• Turnkey solutions tailored to plant needs

• Advanced sorbent milling and injection technologies that improve removal efficiency and reduce sorbent usage

• Support across industries including lime manufacturing, cement, power, oil & gas, and pulp & paper

What technologies does UCC use to enhance DSI performance?

• VIPER® Mill – Optimizes sorbent particle size for better reactivity and lower sorbent consumption.

• COBRA™ Lance – Maximizes sorbent dispersion in the flue gas without added power or compressed air. Reduces sorbent consumption and improves pollutant removal performance.

• Splitters – Ensure even sorbent distribution to injection points to maximize pollutant removal.

• CFD Modeling – Computational fluid dynamics modeling helps optimize sorbent dispersion, sorbent injection locations and performance.

How can we help?

Our team of experts are happy to help answer any questions you have about dry sorbent injection solutions.