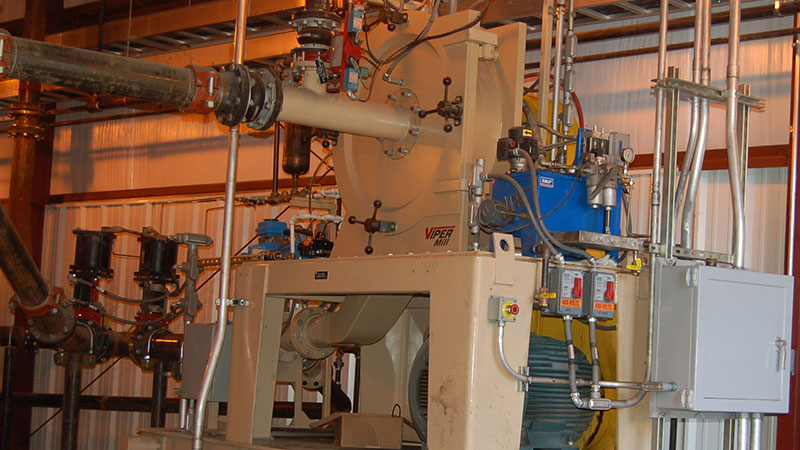

VIPER Mill

The UCC VIPER™ Mill is a proven, reliable technology that significantly reduces operating cost and improves emissions control of dry sorbent injection (DSI) systems. VIPER Mill technology reduces sorbent particle size to enhance removal of SO2, SO3, and HCL.

The VIPER Mill is capable of processing up to 7 tons per hour of sorbent on a 24/7 basis. In a typical SO2 removal application, the VIPER Mill can reduce sorbent usage by 30-50%. In SO3 removal applications, the ultra-small sorbent particle size helps to achieve aggressive ppm targets while reducing usage up to 50%. A single VIPER Mill can reduce sorbent costs by over $3 million annually compared to other DSI systems.

Industry leading UCC DSI technology, including the new VIPER Mill, provides utilities with the most efficient and economical method to meet current and future emission limits and regulations.

Advantages

- Greatest Sorbent Savings in the Industry

- Smaller particle size leads to lower sorbent quantity consumed

- ~30-50% less sorbent used in SO2 application

- ~50% less sorbent used in a SO3 application

- Fastest return on a capital investment

- Saves utilities millions of dollars over the life of the system

- Smaller particle size leads to lower sorbent quantity consumed

- Proven Performance

- Patent-pending in-line automated cleaning system minimizes sorbent build-up

- Filtered and cooled oil lubrication system for long bearing life

- Design proven for 24/7 milling operation in a DSI application

- Wear components are in stock and available for immediate shipment

- Simple Installation and Integration into DSI Systems

- Fully pre-piped and pre-wired mill skids for quick installation

- No secondary downstream sorbent storage required

- Access to all moving parts for easy inspection

- Configurable inlet and discharge to easily accommodate existing line sizes

- The VIPER Mill is configured for low (0.5 – 2 TPH), medium (2 – 4 TPH) and high (4 – 7 TPH) throughput

- Median particle size: 12-15 µm (Trona), 15-19 µm (Sodium Bicarbonate)