What is Solids Dewatering?

Solids dewatering is the process of separating water from industrial sludge or wastewater solids to reduce disposal volume, recover water, and simplify downstream treatment. Effective dewatering is a critical step in Zero Liquid Discharge (ZLD) systems, mobile water treatment units, and full-scale wastewater treatment operations. UCC engineers and integrates dewatering solutions for industries including power, mining, chemical, steel, oil & gas, and microelectronics, ensuring compliance, efficiency, and optimized water recovery.

Why Solids Dewatering Matters

• Reduce Disposal Costs: Lower sludge volume translates into fewer transportation and landfill fees.

• Water Recovery: Recovered water can be reused onsite, improving plant efficiency.

• Regulatory Compliance: Dewatering helps meet ELG, no-discharge, and other environmental regulations.

• Protect Equipment & Processes: Proper dewatering prevents fouling, scaling, and operational disruptions.

Common Dewatering Technologies

UCC Environmental designs systems using the best technology for your wastewater stream:

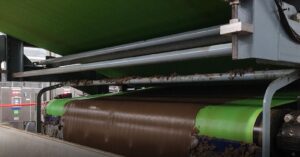

• Belt Presses: Continuous dewatering for high-volume sludge

• Centrifuges: Fast separation for fine solids and high-throughput streams

• Filter Presses: Batch dewatering for chemical sludges and high-solids waste

• Screw Presses & Mechanical Systems: Flexible solutions for industrial and municipal applications

• Mobile Dewatering Integration: Units can be deployed on-site as part of mobile treatment systems for temporary or emergency operations

Integration with ZLD and Mobile Systems

Dewatering is a key component of ZLD systems, reducing solids volume while maximizing water recovery. Our dewatering solutions can also be paired with mobile water and wastewater treatment systems for temporary or supplemental treatment needs, ensuring continuity and compliance even in remote or challenging sites.

Industries Served

• Power generation

• Mining & mineral processing

• Chemical manufacturing

• Steel & metals

• Oil & gas

• Microelectronics

• Municipal wastewater

Wherever solids handling is critical, UCC Environmental delivers integrated solutions that optimize water recovery and minimize waste.

Our Dewatering Capabilies

• Engineering & system design for site-specific applications

• Equipment selection and integration (UCC-owned or third-party)

• Pilot testing and process optimization

• Installation, startup, and ongoing technical support

• Temporary or long-term deployment options

SOLIDS DEWATERING FREQUENTLY ASKED QUESTIONS

What is solids or sludge dewatering?

Why is dewatering important for industrial wastewater management?

What technologies are commonly used for solids dewatering?

• Belt presses for continuous sludge processing

• Centrifuges for fine solids and high-throughput streams

• Filter presses for batch processing of high-solids or chemical sludges

• Screw presses and other mechanical systems

UCC Environmental integrates these technologies to meet site-specific requirements.

Can mobile water treatment systems include dewatering equipment?

How does dewatering integrate with Zero Liquid Discharge (ZLD) systems?

Which industries benefit most from solids dewatering solutions?

What are the advantages of UCC Environmental’s engineered dewatering systems?

• Optimized system performance for site-specific wastewater streams

• Integration with mobile and ZLD systems

• Reduced operating and disposal costs

• Long-term reliability and technical support

Can dewatering reduce operating costs and water usage?

Ready to improve your solids handling and wastewater efficiency?

Contact UCC Environmental today to discuss engineered solids dewatering solutions for your facility.