Flight Conveyors Overview

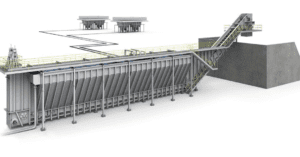

The Submerged Flight Conveyor (SFC) is a proven bottom ash handling system and the most cost-effective compared with other alternatives. Designed for use with most boiler types, this type of system has become the most common bottom ash handling system since the mid-1990s. This system is often used to replace legacy sluice systems and is well suited to new installations where water and headroom are limited.

Not all submerged scraper conveyor designs are created equal. Every aspect of the SFC from UCC is designed to minimize maintenance and to operate dependably from outage to outage. With over 100 installations worldwide, the UCC SFC system has proven to be the industry leader for performance and reliability.

The operation of the Submerged Flight Conveyor (SFC™) is very simple. Ash falls from the boiler into a water-filled, upper trough that quenches and cools the ash. Chains and flights move the ash along the horizontal trough and up a dewatering ramp. At the top of the ramp, the ash falls through a discharge chute into a concrete bunker, where it can be loaded into trucks for final disposal. The conveyor flights continue through the lower (dry) chamber to the rear of the conveyor and then return to the upper trough.

Flight Conveyor Performance Specs

• Continuous ash removal up to 100 TPH

• Less energy and water consumption than sluice systems

• Premium construction for highly reliable 24/7 performance

Upper trough (wet) is lined with thick AR400 abrasion-resistant steel plate for maximum strength and durability

Bottom trough (dry) is lined with thicion-resistant rails or basalt tile for maximum strength and durability

High-strength, robust round chain link is case hardened to UCC specification (approx. 700 BHN) for longer-life durability.

Drive sprocket teeth are made from Durite® H alloy and case hardened for maximum strength and durability

Flights are constructed of rectangular steel tubing, instead of angle iron, to greatly resist and avoid derailment or bending.

Submerged idlers are cast from corrosion resistant, Durite H material (650 BHN) and heat treated for superior life and reliability

Structural support designed to withstand upset conditions.

• The chain tensioner uses a hydraulic cylinder to maintain constant chain tension which extends the chain life and eliminates weekly adjustments common.

• An integral indicator provides visual reference of chain wear. A linear positioner provides an instant alarm if the chain breaks.

• Simple, direct drive soft-start hydraulic motor/reducer provides superior performance and less maintenance over variable speed drive motors.

• The SFC is designed for either variable speed operation, or for two pre-set speeds: normal mode and “catch-up” mode. The higher speeds are used when the unit has been shut down temporarily and a large volume of ash has been collected in the upper trough.

• Modular design simplifies field erection and reduces installation cost

• Optional rollout wheels allow direct access to the boiler throat during a shutdown

How can we help?

Our team of experts are happy to help answer any questions you have about UCC’s solids solutions.