Overview

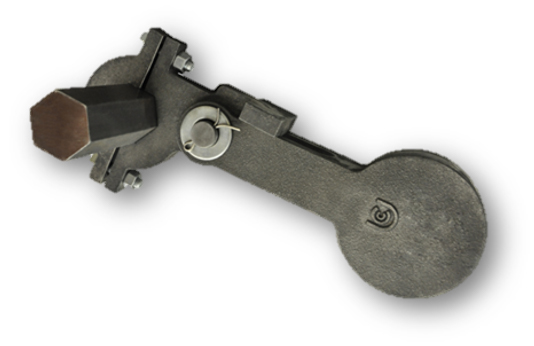

UCC offers a variety of STRYKER Precipitator Hammer models to replace hammers used on precipitators that incorporate both hex-shaft (Wheelabrator CS and DS hammers) and round-shaft (Alstom CRM, ERM, and GD hammers) mounted tumbling hammers. These models provide consistent and optimal ESP efficiency and operation over extended operational lifetimes.

Specifications

• Available Shaft Mounting Shapes: Hexagonal or Round Shaft

• Hammer Material: Ductile Iron w/ hardened steel bushing

• Clamp Material: Cast Steel w/ hardened pivot hole

• Pivot Pin Material: Hardened Steel

Case Studies

UCC STRYKER ll Hammers Provide Significant Cost Savings in ESP Systems

A utility was experiencing premature wear on their OEM Precipitator Hammers, causing a substantial increase in labor and operating expenses. After numerous failures, the plant approached UCC for a solution. Request the full case study to uncover UCC’s solution.

STRYKER IITM Precipitator Hammers Substantially Outperform Competitor Hammers For Significant Cost Savings

A Midwestern Utility was experiencing premature wear and significant damage to the OEM hammers in their Electrostatic Precipitator (ESP), causing an unforeseen increase in labor and operating expenses. The frequent replacement of the hammers resulted in the plant seeking a more cost-effective solution. Read the case study to see how UCC was able to deliver.

UCC Hammers Outperform OEM Hammers for Significant Cost Savings

A coal-fired power plant experienced premature wear and significant damage to the OEM hammers in their Electrostatic Precipitator (ESP). Recognizing the need to address the frequent hammer replacements, which posed an increased risk of downstream equipment failures and resulted in escalating labor and operating expenses, the plant sought a cost-effective solution from UCC. Request the full case study to learn more.

How can we help?

Our team of experts are happy to help answer any questions you have about UCC’s Engineered System Components.