Overview

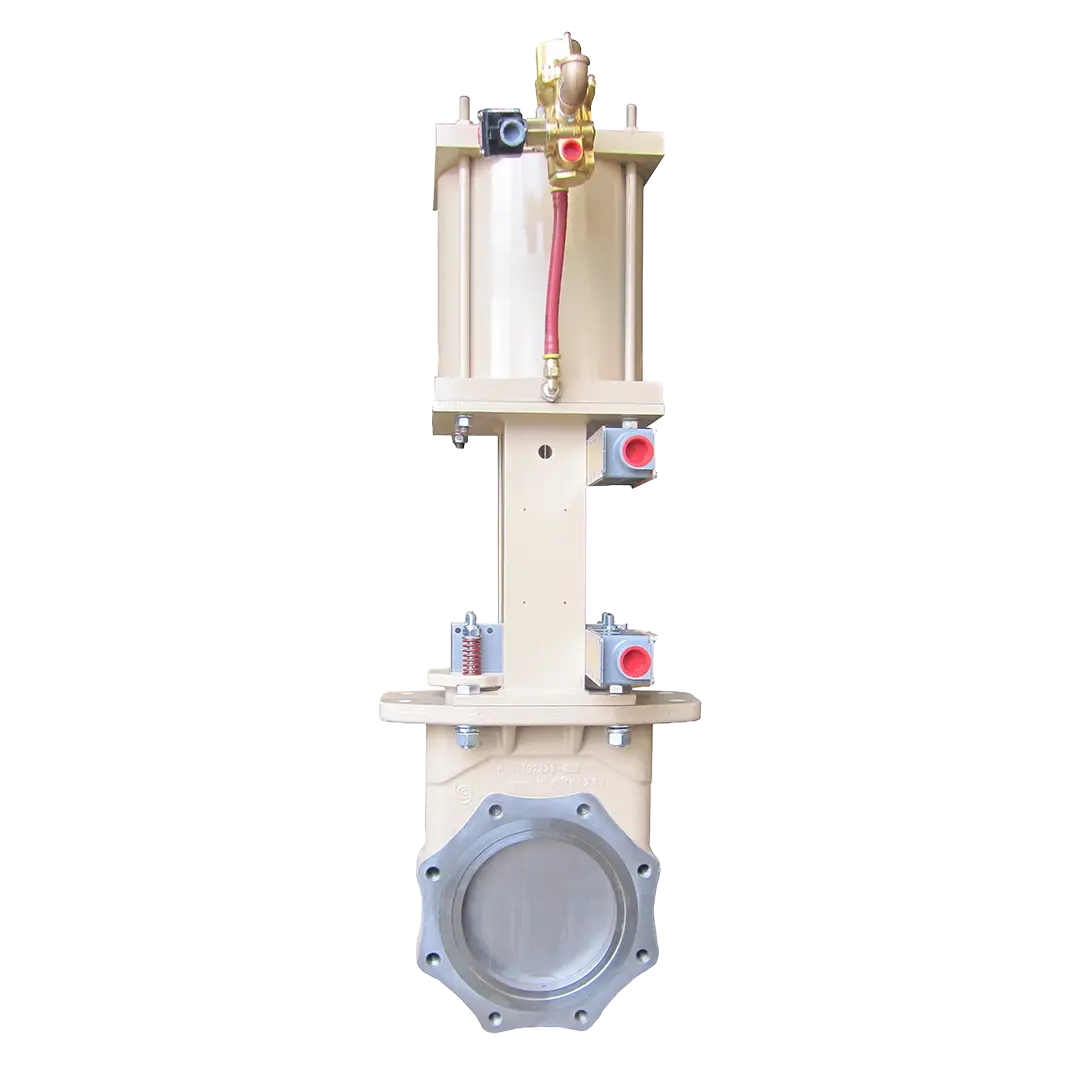

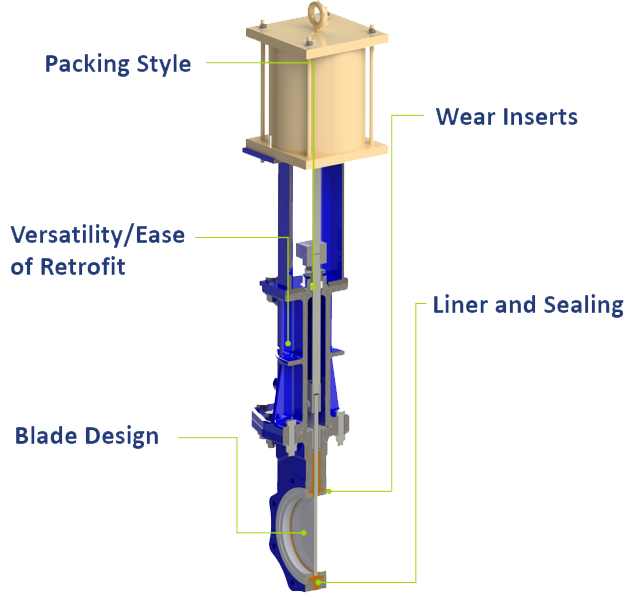

The UCC Environmental 300W Knife Gate Valve is specifically designed for on/off pipeline isolation service in severe-duty hydraulic applications such as bottom ash, pyrites, water supply systems, wastewater, mining, and FGD slurry systems. The pour-in polyurethane liner provides a bubble tight, bi-directional seal and ensures line shut off.

Industries

Cement

Mining

Power

Steel

Water

Features

• Hardened wear inserts to increase valve wear life

• Spring-loaded packing gland with adjustment bolts keeps positive force on the packing, preventing leaks and minimizing required maintenance

• Factory or field-installed bonnet provides a smaller sealing area for fewer leak points and less maintenance

Advantages

Superior Performance

Longer Service Life

Versatile Valve Options

Case Studies

UCC 300W Knife Gate Valve Solves Excessive Leaking Problems

A power plant had non-UCC slurry valves that were leaking excessively in their bottom ash system, causing a significant increase in operating and maintenance expenses. To prove that the leakage in the valves could be prevented, UCC installed a UCC 300W Knife Gate Valve alongside the failing slurry valves and conducted a side-by-side comparison. Read the case study to see the end result.

UCC 300W Knife Gate Valve Solves Excessive Repair and Replacement Costs

A 900MW Northwestern US coal-fired power plant experienced a significant increase in maintenance costs due to the repeated premature failure of OEM isolation valves installed in their bottom ash conveying system. The isolation valves were exposed to highly abrasive material in a high-pressure environment, which caused the valve’s blade to bend. This prevented the valve from sealing properly and resulted in excessive leakage. Read the case study to see UCC’s solution.

How can we help?

Our team of experts are happy to help answer any questions you have about UCC Gates and Valves.