Overview

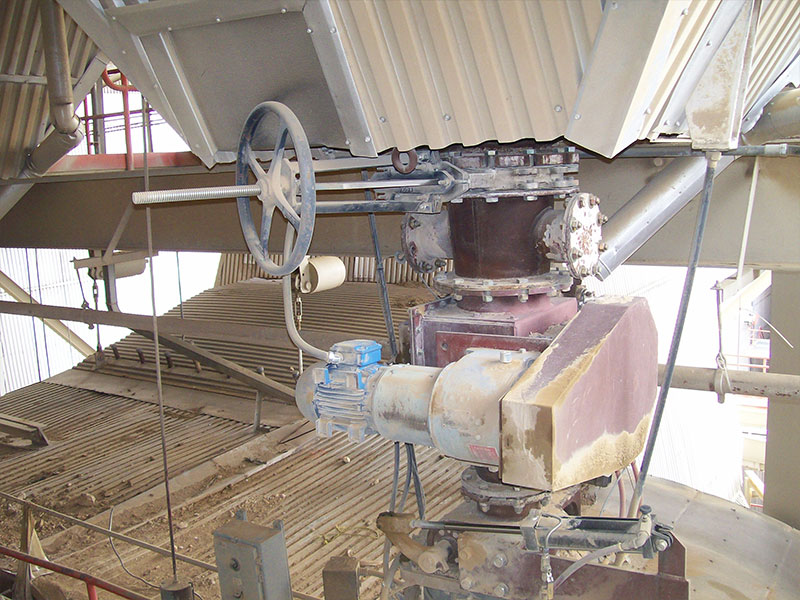

The UCC Economizer EXCEN-CRUSHER® has been developed specifically for processing economizer ash in utility and industrial power plants. The Economizer clinker grinder incorporates many innovative features to minimize wear and downtime and to withstand high temperatures.

Features & Benefits

- Spring-loaded shaft seal – Auto-adjust, spring-loaded packing provides a positive shaft seal with minimum force

- Adjustable Anvil Plate can be angled at either 45° or 60° to provide an optimal angle of attack

- High Torque Drive – The low speed and high torque ensures the production of relatively uniform-size particles without excessive generation of fines

- Abrasive-Resistant Internal Components – Cams and side wear plates are made of DURITE® “H”, chrome alloy white iron (600-700 BHN). Anvil plate and combing plate material is a combination of abrasion resistant plate AR360 (Teeth (400 BHN)) and mild steel A36 (plates).

- Durable Cams: The cams are made with a beefy, square tooth profile for long life. If worn or damaged, the cams can be replaced individually.

- Heavy Duty Bearings are mounted outboard of the crusher where they are easy to service and not subjected to high temperatures or contact with the ash being processed.

- Heavy welded steel frame with round flanges permitting twelve different installation positions

- Designed to handle materials at temperatures up to 1200 °F and pressures up to 60 inches w.c.

- Replacement parts or replacement units are readily available for prompt shipment

- Complete factory rebuilds are available

- Rebuild kits are available allowing crusher units to be completely refurbished at plant